Learn More: Videos to Help You Master Your AI Products and Take Charge of Your Career

|

Featured videos

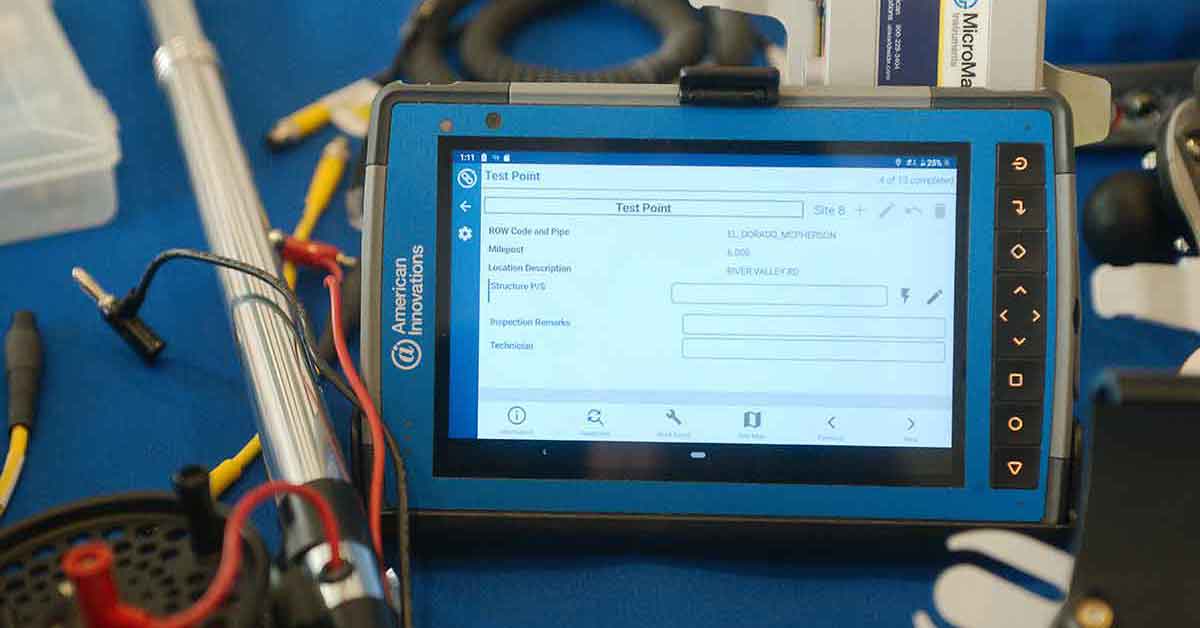

Get to know our products better

To learn more about our products, get in touch with our sales team.