In 2010, a 30-inch diameter natural gas transmission pipeline in San Bruno, CA, ruptured, releasing vast quantities of natural gas. Consequently, the escaping gas ignited and initiated structure fires in the community surrounding the pipeline. As a result, the Pipeline and Hazardous Materials Safety Administration (PHMSA) enacted regulations known as the "Mega Rule." The Mega Rule aims to improve pipeline safety and reduce the frequency of natural gas pipeline failures.

Get a better understanding of the PHMSA Mega Rule at this year's AI World Users Group event, "Mega Rule, Mega Future." This event, catered specifically for the oil and gas industry, offers a priceless opportunity to gain insights and knowledge about this regulation. Attending this event will give you the expertise to navigate the regulatory terrain, develop a deeper understanding of this regulation's many requirements, and discover how technology is helping companies with their compliance efforts.

Mega Rule Overview

The PHMSA Mega Rule is broken down into three separate parts. In brief, Part 1 focuses on ensuring safe operating conditions for transmission pipelines. Moreover, it includes MAOP (maximum allowable operating pressure) reconfirmation and reporting and ILI launcher and receiver facility safety. Additionally, Part 1 extends requirements to additional pipelines in Moderate Consequence areas.

Part 2 focuses specifically on onshore gas transmission pipelines. This important component clarifies integrity management regulations. Additionally, it expands corrosion control to require ECDA analysis after any line backfill event of 1,000 feet or more of pipe. It also mandates inspection after extreme weather, updates repair criteria for both high-consequence areas (HCA) and non-HCA pipelines, and adds additional requirements for Leak Detection on gas pipelines.

Finally, Part 3 takes corrosion control requirements that are standard for transmission pipelines and extends them to gas gathering lines. Consequently, this adds an additional 400,000 miles of pipeline to the PHMSA annual reporting requirements. In addition, it adds a new Type C designation for these gathering lines. It also calls for full corrosion control, leak survey, and repair requirements equivalent to the requirements already standard to transmission pipelines.

In summary, PHMSA expects these improvements to enhance the safety and reliability of the nation's pipeline infrastructure. In addition, they serve to protect the environment and public health.

Whether you’re catching up on the details or starting to research the next steps for your natural gas assets, check out our guide to complying with the PHMSA Mega Rule.

Table of Contents

- What is the PHMSA Mega Rule?

- Understanding the PHMSA Mega Rule: A Brief History

- Mega Rule Part One

- Mega Rule Part Two

- Mega Rule Part Three

- Part Three Key Dates

- Part One Key Dates

- Frequently Asked Questions

- Additional Resources

What is the PHMSA Mega Rule?

Do you work in the pipeline industry? Then you’ve likely heard plenty about the PHMSA Gas Transmission Final Rule, aka the Mega Rule, over the past decade. Thus, as new regulations roll out, assessing the impact on your operations and the steps needed to comply is key.

The PHMSA Mega Rule is a major overhaul of natural gas pipeline regulations implemented in three parts over the past decade. Hence, operators must understand the impact of these regulations on their operations and take the necessary steps to comply. Furthermore, as its name suggests, the Mega Rule is a comprehensive and sweeping set of regulations compared in scope to the introduction of 49-CFR 192.

- Part One went into effect in 2020. It focuses on material verification, assessment expansion, and record-keeping requirements.

- Part Two, which took effect on May 24, 2023, addresses integrity management, corrosion control, and inspection requirements.

- Part Three expands PHMSA's jurisdiction over onshore gathering lines and took effect on May 16, 2023.

With wide-ranging provisions and impact, the PHMSA Mega Rule is a significant development requiring all stakeholders' careful attention.

PHMSA Mega Rule: A Brief History

The PHMSA Mega Rule, a set of regulations passed to enhance pipeline safety and reduce pipeline failures, was implemented in three parts over the past decade. PHMSA issued the Mega Rule in response to a number of incidents that highlighted the need for improved pipeline regulations.

Two key pipeline incidents drove the development of the Mega Rule. First, the 2010 San Bruno natural gas pipeline explosion killed eight people and destroyed dozens of homes. Then, the right-of-way fire in West Virginia in 2012.

These incidents, among others, underscored the need for stronger pipeline regulations and led to the PHMSA Mega Rule. The rule is intended to improve the safety and reliability of the nation's pipeline infrastructure and to prevent future accidents and incidents.

While some of the requirements of the Mega Rule are already underway, requirements for Part Three will take effect on May 16, 2023. It's important for operators to understand the expansion's implications, especially since it's the most recent regulation to take effect. We'll begin with a discussion of Part Three of the Mega Rule before moving on to Part One, which went into effect in 2021. Finally, we'll look at Part Two. Part Two has yet to take effect but includes crucial changes to integrity management, corrosion control, and inspection requirements.

Mega Rule Part Three

PHMSA Mega Rule Part Three expands PHMSA’s regulatory compliance coverage. In fact, it extends their oversight to an estimated 426,000 miles of gas pipelines to the first valve off of the production facility. Furthermore, this encompasses 90,863 miles of Type C gathering pipelines that require more stringent regulatory treatment.

Experts expected Part Two to go into effect in 2021, with Part Three following in 2022. As it turns out, PHMSA published Part Three on August 24, 2022, and it took effect on May 16, 2023. This followed new drilling technologies, surging gas production, and increased volume transported by gathering lines.

PHMSA noted, “Large diameter, high-pressure gathering lines are susceptible to the same types of integrity threats as transmission pipelines. These threats include corrosion, excavation damage, and construction defects. The exemption of these pipelines from the safety requirements of the Federal Pipeline Safety Regulations failed to consider the present risks.”

Part Three imposes a significant new reporting burden on operators. Moreover, it includes new guidelines for incident tracking and reporting requirements and the classification of gathering lines. Compliance with this section of the PHMSA Mega Rule is critical for operators to ensure safety, reliability, and environmental protection.

Mega Rule Part Three Key Dates

| August 24, 2022 | Publication Date |

| November 16, 2022 | Identification of Type C lines |

| March 15, 2023 | 2022 Annual Report Due with new classifications |

| May 16, 2023 | Full compliance with 192.9 |

Achieving Part Three PHMSA Compliance

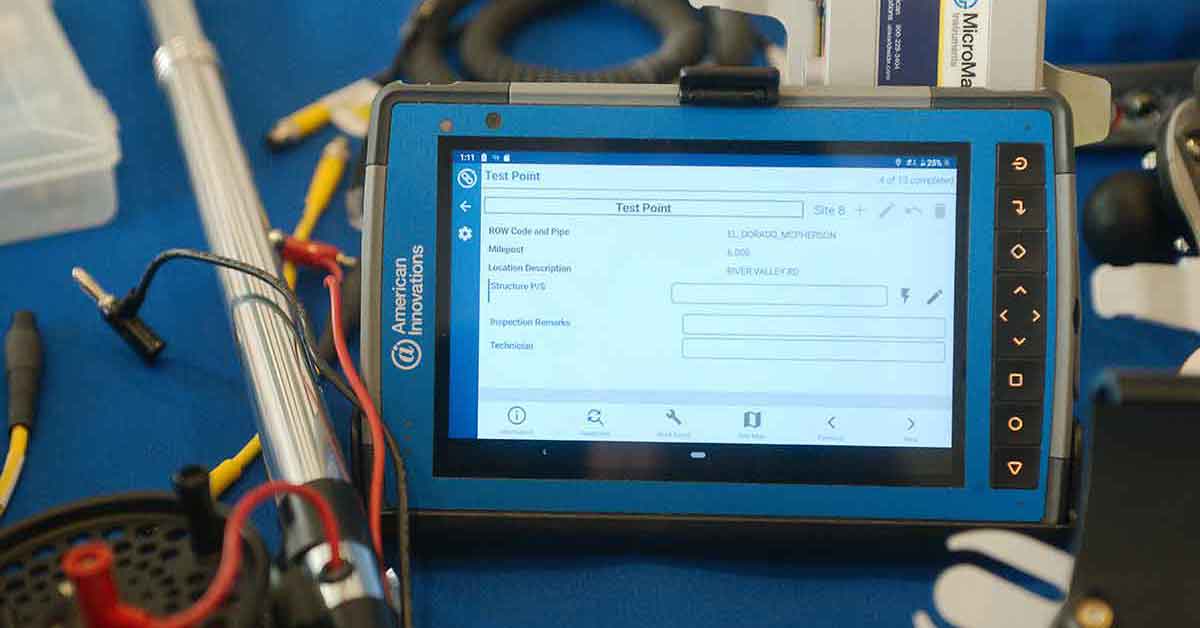

Compliance with PHMSA Mega Rule Part Three can be daunting for operators new to PHMSA regulations. However, American Innovations offers a comprehensive approach to achieving PHMSA compliance to ease this process. Our team can assist in mapping your complete pipeline system. Using our CartoPac Enterprise mobile data solution ensures accurate digitization of your pipeline infrastructure.

In addition to pipeline mapping and data collection expertise, we offer hardware and software solutions to support your compliance program. We also provide mitigation and other hands-on services to ensure you are in full compliance with the new regulatory requirements.

With American Innovations as your compliance partner, you'll be confident that you're taking the necessary steps to meet Part Three PHMSA Mega Rule requirements. Contact us today to learn more about how we can help you achieve compliance with this important regulation.

Mega Rule Part One

PHMSA responded to pipeline incidents and Congressional directives in August 2011 by publishing an Advanced Notice of Proposed Rulemaking (ANPRM) to revise pipeline safety regulations for gas gathering and transmission pipelines. Based on feedback, PHMSA published a Notice of Proposed Rulemaking (NPRM) in April 2016. PHMSA created the "Mega Rule," split into three separate rules. Part One of the Mega Rule, finalized in October 2019, introduced new regulations related to maximum operating pressure. In addition, it identifies Moderate Consequence Areas (MCAs), which are extended covered segments of pipelines.

Operators must have traceable, verifiable, and complete pipeline records to ensure compliance with Part One. They must also confirm the MAOP for qualifying pipelines. Operators must confirm 50% of the pipeline's MAOP in the first seven years of the ruling. Additionally, operators must identify MCAs. PHMSA defines MCAs as areas containing five or more people or dwellings intended for human occupation or congregation, including major roadways. To mitigate hazards, compliance for MCAs requires additional regulations, such as assessment and corrosion protection.

These regulations highlight the importance of inspections and ensuring the material integrity of pipelines, especially in high-consequence areas. In order to achieve compliance with Part One, operators may consider leveraging mobile data solutions and other services offered by engineering firms like American Innovations.

Part One Key Dates

Part One requires a long-term, focused effort to achieve compliance by 2035 and beyond, with roll-out spanning 15 years. Here are the key dates you should know:

| July 1, 2020 | The rule is officially enforced |

| December 30, 2020 | Rule is officially enforced |

| July 1, 2021 | Companies need a plan in place to verify MAOP and identify MCAs |

| July 3, 2028 | 50% of MAOP verification must be complete |

| July 2, 2035 | 100% of MAOP verification must be complete; must have a plan in place to regularly assess MCAs |

The best path forward to compliance includes the right technology to ensure your records are traceable, verifiable, and complete.

Mega Rule Part Two

The second part of the PHMSA Mega Rule is also known as "RIN 2.” It focuses on improving pipeline integrity management best practices. This part of the rule introduces significant changes to integrity, operating, and compliance procedures, which pipeline operators need to plan for ahead of time. This rule also includes new regulations for natural gas pipelines, including regulated onshore gathering lines and pipeline segments. Additionally, the RIN-2 rule includes increased regulatory requirements in 49 CFR 192 for operations and maintenance, integrity management, and data integration. Pipeline operators must operationalize these requirements into systems, processes, and procedures to ensure compliance.

The RIN 2 rule introduces several changes that will significantly impact pipeline operators. These include Data Integration, Risk Assessment, Engineering Critical Assessment for Dents, and Management of Change. Gas pipeline operators must establish an external corrosion management plan to limit the effect of electrical interference. In addition, they must conduct close-interval surveys in areas where cathodic protection is below appropriate levels. Another requirement for pipeline operators is to monitor and mitigate internal corrosion. They must establish a continuous program to check affected areas for corrosive gas.

Pipeline operators must comply with these new regulations for regulated onshore gathering lines and pipeline segments to ensure they fully comply with the PHMSA Mega Rule. Furthermore, PHMSA compliance will require significant changes to your integrity, operating, and compliance procedures.

Part Two Recap — Cathodic Protection and Corrosion Requirements

- Cathodic Protection. Gas pipeline operators must have an external corrosion management plan in place to limit the effect of electrical interference through surveying and assessment. They must then make efforts to mitigate this corrosion in a comprehensive manner alongside other test results.

- Close Interval Surveying & Assessment. If any pipe-to-soil measurements indicate that cathodic protection is below appropriate levels, the pipeline operator must conduct close-interval surveys. In order to comply, operators must conduct close interval surveys (CIS) approximately every five feet in the affected area. In addition, they must remediate any issues within 12 calendar months.

- AC Interference Monitoring. Previously, pipeline operators had to “consider” a recurring or continuous AC interference program to control and monitor accelerated corrosion due to power lines. Part Two now solidifies this request for “consideration” into a true requirement within 6 calendar months.

- Internal Corrosion: Pipeline operators must establish a continuous program to monitor and mitigate internal corrosion. If they find the pipeline is actively transporting corrosive gas, they must check affected areas at least twice annually using coupons or other relevant methods.

Achieving Part Two Compliance for the Gas Transmission Final Rule

Part Two of the PHMSA Mega Rule for Gas Transmission Pipelines introduces several new regulations requiring careful attention and compliance from pipeline operators. To ensure compliance, operators must have comprehensive programs in place for cathodic protection, internal corrosion monitoring, and risk assessment.

At American Innovations, we help pipeline operators review their operations and best practices. This includes updating their records using our Pipeline Compliance System (PCS) hardware and software solutions. In addition, we offer a tailor-made continuous program for internal corrosion monitoring using our CartoPac Enterprise mobile data collection solution. Furthermore, CartoPac takes into account all the factors necessary to develop an effective corrosion management plan.

We also provide support for close-interval surveys and cathodic protection data gathering with our PCS Field Integration solution.

American Innovations provides the expertise and tools pipeline operators need to develop a plan of action that addresses all PHMSA Mega Rule Part Two requirements.

If you need assistance in achieving compliance with the PHMSA Mega Rule, contact us for a consultation today.

PHMSA Mega Rule FAQs

Visit PHMSA's Frequently Asked Questions (FAQs) on the Gas Transmission Final Rule

The Mega Rule refers to a set of pipeline safety regulations issued by the Pipeline and Hazardous Materials Safety Administration (PHMSA). The official name of the rule is "Safety of Gas Transmission and Gathering Pipelines." It is part of PHMSA's ongoing efforts to improve the safety of the nation's pipeline infrastructure.

PHMSA 192 Mega Rule is a set of pipeline safety regulations that PHMSA issued under Title 49 of the Code of Federal Regulations (CFR), Part 192. Issued in October 2019, the PHMSA 192 Mega Rule includes significant changes to hazardous liquid pipeline regulations.

The PHMSA Mega Rule Phase 3 is the final part of a set of pipeline safety regulations issued by the Pipeline and Hazardous Materials Safety Administration (PHMSA).

The PHMSA leak detection rule became effective on February 1, 2021. It requires hazardous liquid pipeline operators to implement leak detection systems that can detect leaks promptly and accurately.

Additional Resources

[Presentation] AI World 2022: Expanded Mega Rule Compliance

American Innovations, Bass Engineering, and Cartopac Enterprise experts discussed PHMSA's Gas Transmission Final Rule during the 2022 AI World Users Group conference. Download the presentation to see more details about their presentation.

[Presentation] Mega Rule Compliance: Using Technology to Meet New Regulations

Becky Gibbs Murray's presentation on the Mega Rule for the Rocky Mountain Short Course on 1/20/2023 covered a brief history of the Mega Rule, how to leverage technology to achieve compliance, and the many challenges associated with each part of this regulation.

[Video] Virtual Brew 1/19/2023:

PHMSA Mega Rule: Leverage the Right Technology to Ensure Compliance

Watch the Virtual Brew webinar about the PHMSA Mega Rule. Learn how you can use technology to achieve compliance with this regulation.

[FREE Materials Performance Webcast] How to Use PHMSA Incident Data for Building Predictive Models

Now Available On-Demand

Find out how to evaluate machine learning and implement predictive modeling using PHMSA public incidents and annual reports. Predict the variables that affect the outcomes you should care about. Also, know the chances of your assets having an incident, the likely costs, and the most likely causes.

[Video] American Innovations Interviewed on Mega Rule

Materials Performance Editor-in-Chief Rebecca Bickham talks with Andrew Holle Sr. Principal Systems Architect of American Innovations on Mega Rule and its role in the pipeline industry.

Looking for a comprehensive approach to pipeline management and compliance with the PHMSA Mega Rule? Contact us for a consultation.

↔